Biological scaffolds for regenerative medicine

The company SpinPlant GmbH from Saxony-Anhalt makes a new type of biological scaffold in an electro-spinning process

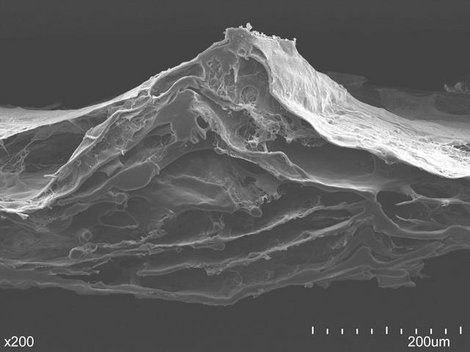

In the scope of a unique electro-spinning process and in cooperation with the Fraunhofer Institute for Material Mechanics (IMWS), the company SpinPlant GmbH in Halle (Saale) has made a new form of biological scaffolding. The way it differs from all comparable products: the stable biological scaffold consists of a combination of nano- and micro-porosity, something which has never been achieved before.

Collagen is one of the basic building blocks of our body, the natural environment of bone and skin cells in particular. Accounting for more than thirty percent of the total weight of all proteins, collagen is also the most abundant protein in the human body.

SpinPlant, a young company from the German federal state of Saxony-Anhalt, is presently redefining the use of natural collagen. In this context, it is using bovine materials, in this case, collagen which is made from cowhide. With the help of electro-spinning, SpinPlant has succeeded in creating structures which correspond to the natural environment of the cells in the human body. In this context, the collagen is obtained as a natural protein and therefore remains biologically active.

The biological scaffolds produced by SpinPlants therefore form a natural environment for the cells of the human body. As a platform technology, the scaffolds can be put to a variety of uses. “Our scaffolds are used in the field of regenerative medicine. They are suitable for cell therapy, for use as bone filler material, for bone formation in dental medicine, as a tissue substitute and in the treatment of chronic wounds,” explains Managing Director Dr. Christian Herbst.

The collagen stays native

The scaffold is manufactured in cooperation with the Fraunhofer Institute for Materials Mechanics (IMWS) with the use of a unique electro-spinning process. This enables the manufacturing of particularly thin filaments in the nano-scale which have a micro-porous structure. The scaffold consists of several layers through which the cells are able to grow. The cells are also able to adhere to the nano-filaments so as to agglomerate and segment. Their difference from conventional products consists of their combination between nano- and micro-porosity. Despite the complicated nature of the production process SpinPlant has also succeeded in maintaining the natural status of the collagen. “This means that the biological activity of the protein is maintained, and therefore the ability of the material of collagen to communicate as well.” In this way, Christian Herbst explains, the natural attributes of the collagen are able to take effect. Two of these are of considerable importance: firstly, the collagen is anti-inflammatory, which has previously been demonstrated in animal experiments. Secondly, with the use of the collagen, the bio-synthesis of the surrounding cells can also be initiated. Dr. Herbst: “We have also provided our collagen with additional osteo-inductive additives for example, and in subsequent animal experiments, we have been able to demonstrate that we can convert normal stem cells into osteoblasts, i.e. bone cells.”

SpinPlant pins hopes on rapid approval in the USA and Europe

The company is pursuing two marketing approaches. On the one hand, it wants to become established as a supplier to cooperation partners in the USA and Europe. On the other, SpinPlant also wants to market its own end-products: its bone filling material SpinFill, which supports the growth of bones in orthopaedic and dental applications, and SpinHeal, a wound-healing product used for the treatment of severe and chronic wounds so as to speed up the healing process. Additional end-products are also being researched and developed.

The finished products are currently going through the process of certification; SpinPlant is expecting SpinFill to be approved in America later this year, and by the end of 2018 in Europe.

The company was founded by its shareholder, Professor Hans Jörg Meisel, Head Physician at a hospital in Halle and a leading scientist in the field of regenerative spinal medicine; Dr. Timothy Ganey, Scientific Director in the Orthopaedic Department of the Atlanta Medical Center, and Commercial Lawyer Dr. Christian Herbst. The private “GmbH” company has two locations in Central Germany: in Leipzig, Saxony, and the production location of the company in Halle, Saxony-Anhalt. It chose Saxony-Anhalt due to the many advantages which it offers. Its cooperative partner and co-shareholder, the Fraunhofer IMWS is based in Halle; the company has also received considerable support with the research and development of its products on the basis of a joint research project with the University of Magdeburg, the regional capital of Saxony-Anhalt, in the scope of which SpinPlant also provides the funding for a professorship. “And thirdly, here in Saxony-Anhalt, we have also received excellent support from the Investment and Marketing Corporation. When it comes to funding, our position is strong, and we feel very much at home here,” says Dr. Christian Herbst.

Author: Anja Falgowski