Battery and Energy Storage in Saxony-Anhalt

In electromobility, the battery is of central importance as an energy storage device. Saxony-Anhalt is ideally positioned as a location for battery cell production in Germany - from battery chemicals and material production to battery development and testing. This is because it is not only HERE that the materials for this are supplied and the battery for tomorrow is developed further. In the area of storage solutions and with its competencies in battery endurance testing, the state is ideally positioned here.

Saxony-Anhalt thus offers potential and innovations along the entire value chain for lithium-ion batteries. And it creates the basis for competitiveness and employment for companies - and also for the e-mobility of tomorrow.

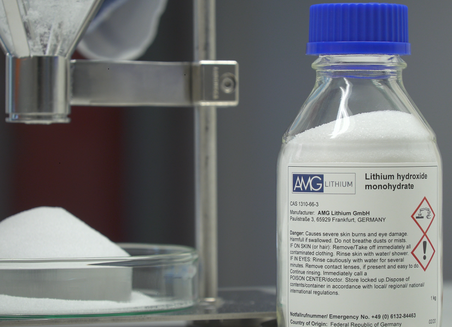

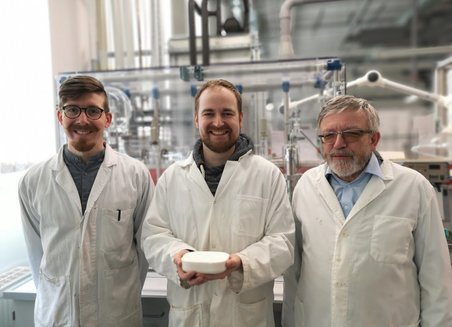

Battery Materials and Component Development for Battery Cell Production

Saxony-Anhalt has great know-how in the field of material development as well as the development of manufacturing processes and components for modern energy storage applications. HERE innovations are created for automotive suppliers, battery manufacturers or cell producers as well as for material developers. The fields of application of the battery cell are manifold - from computers, cell phones, electrical appliances and devices for professional and private everyday life, but increasingly also in electromobility and large-scale storage solutions.

success stories

Battery Development and Battery Testing

Saxony-Anhalt is ahead of the game when it comes to battery development. From conception to the production-ready series battery, the companies at the location provide all the answers to the questions that arise in the context of battery production. For application as energy storage or in electric cars, development and test centers in the state offer performance tests, endurance tests, environmental, mechanical, safety and abuse tests, also for high-voltage batteries, to ensure the key requirements of battery and car manufacturers for high energy density, durability, reliability and safety.

Success Story: FEV eDLP - world´s largest development and test center for high voltage batteries

In Saxony-Anhalt, the FEV Group runs the world´s largest development and test center for high voltage batteries for passenger and commercial vehicles (eDLP).

The FEV eDLP offers performance and electrical tests, tests on environmental and mechanical impacts, as well as abuse tests for battery cells, modules and packs, plus other components. A wide range of climate zones can be reproduced – from -40°C to 90°C. Another unique feature is a 350 kN shaker that can be used to carry out combined mechanical and electrical tests on batteries as well as charging and discharging under vibration stress. With the eDLP, the The FEV Group continues its success story with the business location of Saxony-Anhalt, which began in 2007.

FEV eDLP in brief - in sound and vision

Li-Ion Battery Requirements

Heavyweight for Sustainability

The most complex Test

Necessity of Battery Testing

Conditions for Battery Cell Development

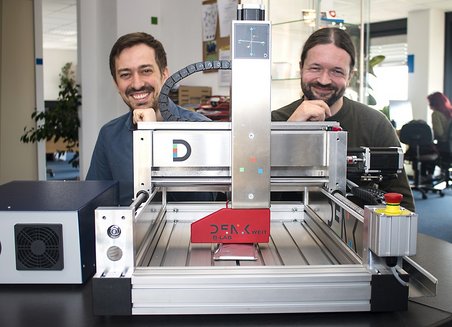

Success story: HORIBA FuelCon GmbH - Test benches for batteries and fuel cells

The latest batteries and energy management systems are key requirements for the mobility of the future. Analyses of their service life, performance, degradation and cycle stability form part of the tests completed by HORIBA FuelCon GmbH.

With test benches for AIRBUS, Audi, BMW, BOEING and other OEMs, the company is a leading manufacturer. Its products range from small cell test benches, large fuel cell systems, to large battery packs that are used as a traction battery for motor vehicles. HORIBA FuelCon GmbH has been an expert in the area of high-performance solutions for several years. On the basis of test parameters of -40 °C to 120 °C on battery test benches and the TrueData impedance analysis unit, the determination of precision measurement data is possible.

other success stories

Battery Manufacturing, electric Cars and Energy Storage Manufacturers

The conditions for battery production companies, for example for electric cars, as well as for manufacturers of energy storage systems find perfect conditions in Saxony-Anhalt, both in terms of battery production and sales. Innovative producers have gained a foothold here and are growing with energy.

Location factors for battery production in Saxony-Anhalt

Saxony-Anhalt has diverse competencies that make the state a battery location.

Saxony-Anhalt forms the core of the Central German chemical triangle and is one of the world's most attractive locations for the chemical industry. The materials for battery production are created here.

In Saxony-Anhalt, components, systems and technologies are created as predevelopment for the automobiles that OEMs will implement tomorrow. HERE, processes are optimized for new, manageable and quickly implementable technologies.

Well over 2,000 innovative and in some cases internationally active ICT companies with around 16,000 employees are currently based in the state. The majority are active in software development and IT services for other companies.