Industry 4.0 in Saxony-Anhalt

After Thomas Newcomen's pioneering invention of the steam engine, the development of assembly line work and Henry Ford's mechanization of production, and John Parson's first numerically controlled machine, we are now in the midst of the fourth industrial revolution.

In Saxony-Anhalt, production is interlinked with state-of-the-art information and communication technology. The driving force behind this development is the rapidly increasing digitisation of the economy and society.

Read and see here about technologies, solutions, applications and examples of intelligent and flexible productions:

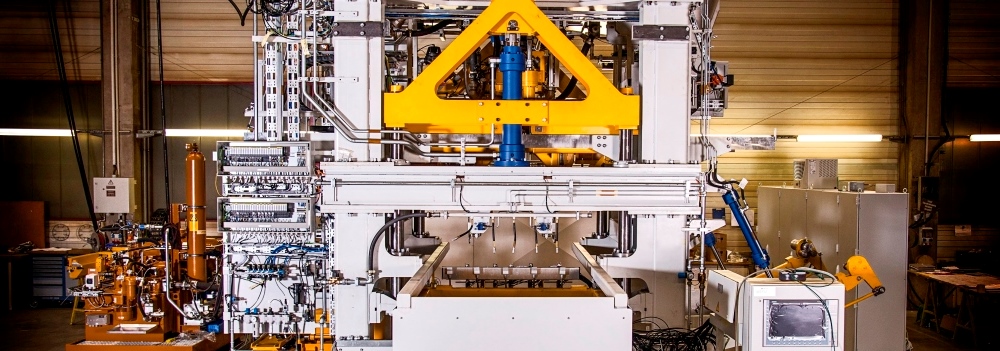

Industrial Automation

Only those who rely on modern automation technologies will be at the front in the digital race

Primarily medium-sized enterprises such as Rubicon GmbH make Saxony-Anhalt a high-performance region in the sphere of mechanical and plant engineering. 150 years of experience constitute the basis for the most important of all industries in the federal state. Over 12,000 employees in the 71 companies compiled a turnover of about 2.1 billion euros in 2020. (Source: VDMA)

Industrial Automation in Video

Why is industrial automation important and what changes in terms of procedure? Laempe Mössner Sintro GmbH, NTN Antriebstechnik GmbH and JS Lasertechnik GmbH from Saxony-Anhalt let you know.

Laempe Mössner Sinto GmbH

JS Lasertechnik GmbH

NTN Antriebstechnik GmbH

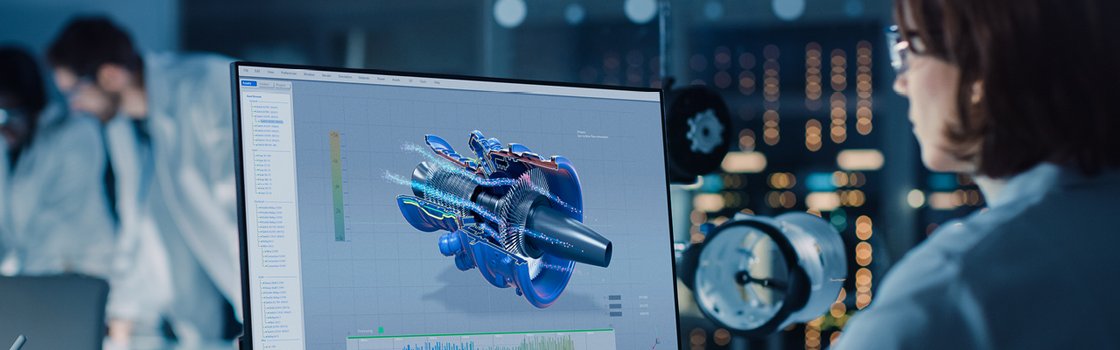

Digital Planing

There is no more planning on the drawing board. 3D software solutions for virtual planning, simulation and visualization of complex manufacturing processes are the status quo today.

Investors and companies can simulate the system before building a production plant or logistics center. A 3D process visualization is nowadays indispensable before large projects are implemented. The advantages are obvious: more precise planning, higher production, greater safety and efficiency, lower energy costs.

Success planned digitally

3D Printing & Industry 4.0

From the computer directly to the product - that's what modern manufacturing, called Industry 4.0, is aiming for.

Additive 3D production is regarded as pioneering because it can produce high-quality products with often fewer resources and thus more environmentally friendly than before. Additive manufacturing technologies can help to reduce product development time by transferring computer-designed products directly to reality - 3D printing.

Printing in three dimensions

Factory of the future

In the age of digital networking, the demands placed on modern production facilities are increasing.

In order to master this complexity, many approaches and methods have been developed in recent years to plan future-proof factories. Interconnecting these solution elements leads to industry 4.0 and a digital factory of the future is expected to fully integrate these solution elements. This article describes what challenges arise during planning and how to overcome them.

Insights into the factory of the future

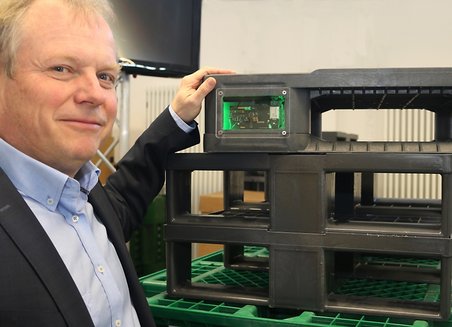

Artificial Intelligence, Predictive Maintenance & Chemicals 4.0

Artificial intelligence in industrial maintenance & industrial chemistry 4.

What if you were able to foresee a system failure in the long term or if you could determine when maintenance should really be carried out? Imagine being able to control and manage maintenance costs, downtime and stock levels effectively and in the long term!

What does industry 4.0 look like in the chemical and plastics industry? Chemicals 4.0 describes a living, long-term process that encompasses both product development and organizational structures.