Chemicals parks: High degree of competitiveness

Dr. Norbert Malanowski from the company VDI Technologiezentrum GmbH attributes a high degree of competitiveness to the chemicals parks in both Saxony-Anhalt and throughout Germany. As a project manager, he follows developments in the chemicals industry very closely. A short research paper entitled “Innovations- und Effizienzsprünge in der chemischen Industrie? Wirkungen und Herausforderungen von Industrie 4.0 und Co.” (Gains in innovation and efficiency in the chemicals industry? The impact and challenges of industry 4.0, etc.) was published in 2014, and the results of the major research project are set to be published by the end of this year. While the manufacturing industry has been the focus of previous projects, Malanowski has focused on the process industry, which is increasingly referred to with the term “Chemicals 4.0”. "The digitisation of the process industry is the current topic and is set to be of decisive importance for the future viability of companies which operate in the chemical and plastics industries," explains Malanowski. "In this respect, the spotlight is on the topics of networking, digital intelligence and autonomy.”

Solutions for these topics are undergoing intensive research at the scientific institutions in Saxony-Anhalt and being put into practice in partnership with an innovative ICT sector. This is an area in which the Otto-von-Guericke-University Magdeburg, the Fraunhofer Institute for Factory Operation and Automation (IFF) and Tarakos GmbH, a specialist company for simulation software and 3D simulation, all stand as examples.

While just a few years ago, the necessity for digitisation was still being questioned, the processes are long since under way and being implemented at different speeds. "It is particularly important to get people on board," explains Malanowski. He views the trio of man, technology and organisation as the key to success for the future of the chemical industry – another area in which chemical parks offer great advantages due to their synergies and the active transfer of knowledge between both large global players and small-scale specialists.

Networked since 1996

The concept of the chemical park was invented in Saxony-Anhalt. The first parks were set up in 1996 at the locations of Zeitz/Elsteraue and Leuna, and provide for close networking between companies, technological synergies and the efficient use of the available resources. Further settlements have since followed in Bitterfeld-Wolfen, Schkopau and Piesteritz. Their sophisticated infrastructure and efficient networks make the sites attractive in the competitive international environment. Chief Operating Officer Daniel Böke of CBW Chemie GmbH, which is based in Bitterfeld-Wolfen, describes the advantages offered by the parks as being their structure which supports fair, market-oriented business, the support provided by the IT infrastructure, the on-site supply systems, the feeling of joint security, as well as advantages in the area of personnel costs.

Above all else, Böke views the “Chemicals 4.0” in terms of digitalisation, which has been actively realised at CBW Chemie GmbH over the last two years with the implementation of an ECM (Enterprise Custom Management) tool, for example. “Over the medium term, the use of all the data available in our company – the keyword being big data – will yield considerable potential for added efficiency,” explains Böke. “This represents a key part of the task of securing the future of Germany as a chemicals location over the long term and maintaining its competitive advantages.”

To be well equipped for the future, Malanowski also believes there is a need for funding programmes which not only take technical developments into account, but also human resources. "It is immensely important for employees to understand how digitised production works and the benefits that the changes are bringing," explains Malanowski. In particular, he expects innovations to take place in the area of new business models. "Who knows, in the near future it may even be possible to print drugs such as painkillers directly at pharmacy stores," he says, highlighting one possible development.

A leader thanks to a German-American tour-de-force

The phrase “Chemicals 4.0” describes a lively, long standing process which encompasses both product developments and organisational structures. In this area, a best practice example can be seen to exist in Saxony-Anhalt in the form of the company PURAGLOBE Germany GmbH, which is located at the Zeitz Chemical and Industry Park in Elsteraue. This 100% subsidiary company of an American corporation has now been operating facilities for the production of base oils in Elsteraue since 2004. Each year, the company converts some 150,000 tonnes of used oils into high quality group II+ (API) base oils. In addition to other areas, the base oils find use in the high performance lubricants of many German manufacturers, including ones in Saxony-Anhalt. Puraglobe is the only company to offer the patented HyLube™ and HyLubeSAT™ processes for the recycling of used oils.

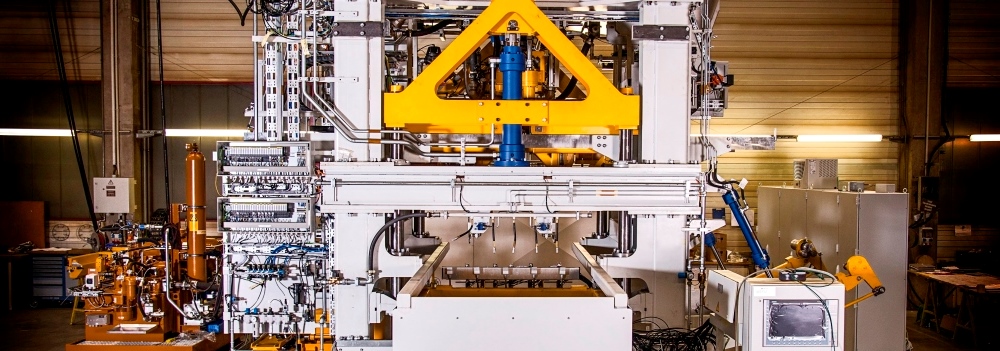

Its latest technological development is the HyLubeSAT™ process, with which used oils are being used to manufacture group III base oils at a production plant in Saxony-Anhalt for the first time. The higher performance of these oils results in low levels of friction in engines, and reduces their fuel consumption and therefore their CO2 emissions. This makes Puraglobe the only supplier of sustainable group III base oils manufactured from used oil which also has CFP (carbon footprint) certification from NSF International. With an investment of approximately 15 million Euros and the creation of another 30 jobs, the American company is clearly committed to its location in the heart of Germany.

That is just the start, however. “It is in Saxony-Anhalt that we are developing the American and international markets,” explains the Managing Director of Puraglobe Andreas Schüppel. “Following from our success in Germany, we are now advancing international projects. Over the medium term, we intend to use the success of our production facilities in Zeitz as a springboard for setting up plants along the same lines in Tampa, Florida, for example”. In this respect, identical plants are planned with completely uniform designations, the technical management of which will take place in Elsteraue, where one to two engineers will be appointed for each installation. They will also ensure the optimum production sequences and take charge of the quality assurance at the international locations. Data packages will be exchanged on a digital basis, while the actual settings on the systems will be completed on site, independently of the internet, for safety reasons. The IT consultants Baumgarten GmbH, which is based nearby at Zeitz Industry Park, is responsible for the data security.

“We need to ensure that our products are always of the same quality, irrespective of where they are manufactured,” says Schüppel, describing the sophisticated process. For Schüppel, the Chemicals 4.0 has long since been part of everyday life. “We took the 2008 economic crisis as an opportunity for change, and in 2009, we convinced our shareholders of the need for the new investments and developments.” With the commissioning of the new facility in Elsteraue, an initial milestone has now been passed. The intensive preparations and plans have made the ultramodern and efficient company fit for the future. Puraglobe represents several innovative companies and businesses in Saxony-Anhalt, which are looking to the future well prepared.