The intelligent pallet sends signals while in transit

The Fraunhofer IFF Magdeburg drives Logistics 4.0 forward in Saxony-Anhalt

Industry 4.0 requires the digitisation of logistics. In Saxony-Anhalt, economy and science are closely linked, in order to develop application-oriented technologies as well as interactive assistance systems for the Industry 4.0. The “intelligent pallet” is an innovative approach in this direction. The pilot project is run by the Fraunhofer Institute for Factory Operation and Automation Magdeburg IFF with partners from the industry and economy.

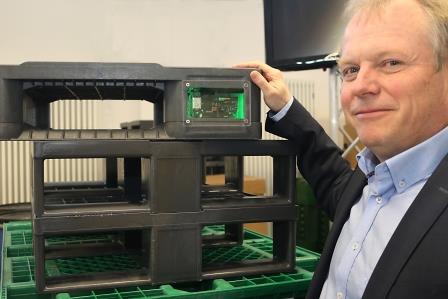

The “personal pallet”

“Each of us has their own personal pallet”, Klaus Richter smiles and places his at the top on a pile of plastic pallets - as a photographic model. The intelligent pallet in the Internet of Things (IoT), as it is called officially, becomes an eye-catcher when he switches on the green light, which illuminates an electronic board behind a viewing window. Those who have a sense of and an interest in logistics will get curious here. “At the German Logistics Conference in Berlin, the representatives of the state criminal police office also asked for details about what research we conduct here”, Klaus Richter says. He is a scientist at the Fraunhofer Institute for Factory Operation and Automation IFF in Magdeburg. The material flow technician with a doctorate is an executive head at IFF in the logistics area. “Industry 4.0 would not be possible without Logistics 4.0”, the expert explains. Within the logistic cycles, pallets, boxes and containers are also in transit. And these all too often get lost - which also explains the criminologists’ interest.

More safety, transparency and efficiency in logistics

The Fraunhofer IFF researches in a practically oriented way and is explicitly familiar with the needs of the logistics industry, which has to be prepared for the digital age. More safety, transparency, efficiency and cost savings play a significant role here. These wishes, Richter says, are now easier to put into practice thanks to the new energy-efficient wireless connections. The scientist mentions the 5G network or the digital communication technology LPWAN; the letters stand for Low Power Wide Area Network. “The new transmission technologies”, Richter states, “now ensure cost-efficient data transmission over a long period of time, over the entire life of a logistic item, as it were.”

With its integrated wireless and sensor module, the Intelligent Pallet becomes a part of the “Internet of Things”. This means that it communicates data via internet to its IoT Cloud without anyone getting involved. At the same time, you can read on the computer where the pallet is located on its transport route, what its status is, what happens to its load or which route materials take within a manufacturing process. The latter could give a better “feel” for complex workflows in the production process, Richter explains, citing a large car manufacturer with its many supply companies as an example. The automotive manufacturer is a partner in the pilot project “Intelligent digital container”. It also includes a variant of the intelligent pallet in a feasibility study.

Basis for success: economy meets science

The scientist talks about a previous tried and tested model which has been used productively in the retail trade for several years: the Heilbronn pallet. The Fraunhofer IFF developed it together with the partners metraTec GmbH, Telent GmbH and Cabka IPS. A retailer operating Europe-wide uses these pallets for goods tracking - from production and the central warehouse to each individual branch office. Furthermore, as the material flow expert says, seamless transparency is reached in empty pallet management with the aid of the integrated identification transponder. This thus ensures that sufficient load carriers are always available on the production site, in order to guarantee a continuous flow of goods. “In this pallet cycle, well over two and a half million pallets are now used - with a rising trend”, Richter emphasises.

A further development of the Heilbronn pallet is the aforementioned Intelligent Pallet in the Internet of Things. This enables almost seamless goods tracking. Pallets are transported to external clients on closed transport chains inside the company as well as on open routes every day. “In addition”, Richter says, “the sensors record excessive vibrations or deviations from the required temperature range. This information is sent via the IoT Cloud to the user in real time. They can take countermeasures immediately.” Another advantage is increased security against theft. The pallets or also building site containers report via the IoT Cloud when they are removed from their current storage space. This could even still prevent a theft.

Commitment to sustainability

Fraunhofer IFF is also developing this smart pallet in collaboration with metraTec GmbH from Magdeburg, which manufactures the electronic board; IoT solutions for smart communication channels come from Telent GmbH in Stuttgart; Cabka IPS is the manufacturer of plastic pallets. The expected applications of the integrable wireless and sensor module would give the company a new impetus in the logistics industry and open up new business fields, Klaus Richter predicts. Cabka IPS have seen this for themselves. The Thuringian company manufactures pallets and boxes made of up to 100 percent of recycled plastic. The economically and ecologically sustainable products are sought-after worldwide. Those who buy these pallets make a commitment to the conscious and careful handling of resources. “The price of a wooden pallet starts at three Euros, the high-quality pallet made of plastic costs between € 25 and 30”, Klaus Richter says. But this price corresponds to a lifespan which is at least seven times longer than that of a wooden pallet. Richter does not need to emphasise what financial losses this involves for the owner, if these pallets get lost.

The logistics expert makes it clear which options are provided with sensor data collection: Companies have a permanent overview of the location and movement of its cargo, and customers know exactly when the product reaches them. In addition, pallet and container management could be optimised in large warehouses. Prototypes of the smart pallet should now be tested by the retail trade. “What’s more, in practice, the wireless and sensor module will be the exact opposite of a large bright eye-catcher. In miniature size it is affixed in a concealed place.

Author: Kathrain Graubaum