Mobility Industry

Pioneer in Production and Application

Cruising around? Not with us: we step on the gas! A component from Saxony-Anhalt is in every car built in Germany. Specialists who supply VW, Daimler, BMW, Opel, Porsche and all major original equipment manufacturers (OEMs) with components have settled here in the competence centre for the automotive supply industry. Their ideas are our fuel.

Heartland of Suppliers

A total of 260 supply industry companies are already benefiting from Saxony-Anhalt’s logistically optimal location in Germany and Europe: a maximum 150 kilometres lie between then and the OEMs. By now, more than 23,000 specialists work in special fields such as drive technology, lightweight construction or e-mobility. IFA Group in Haldensleben is the largest supplier and European market leader in the field of longitudinal shafts.

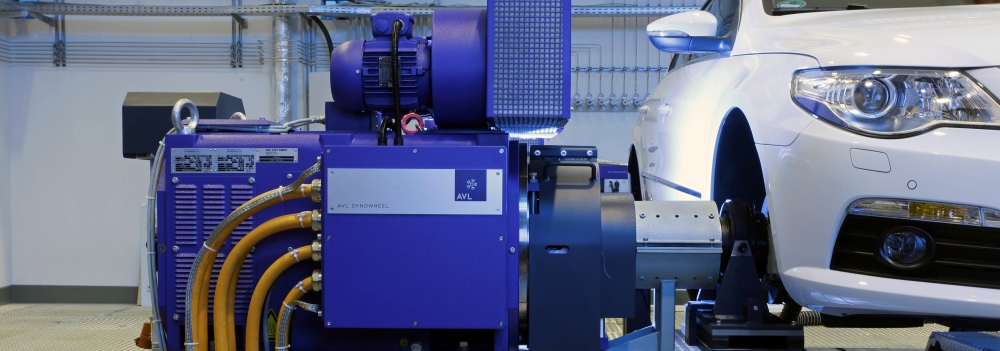

An efficient centre for industry-related research and development has been created here with the Institute for Competence in AutoMobility (IKAM). Moreover, the “Cluster MAHREG Automotive” takes care of the close interconnection between industry and science.

Facts

- Around 260 companies with over 23,000 employees

- Leading position in competency cluster “Aluminium – alloy development and innovative casting methods “ within the ACOD (Automotive Cluster of Eastern Germany)

Core competencies:

- Light metal casting

- Engineering services

- Powder metallurgy

- High performance composites

- Custom machines

Advantages

- Efficient processes due to proximity of large automobile manufacturers

- Central location in Germany and Europe

- OEM Plants (Original Equipment Manufacturer) such as VW, Daimler, BMW, Opel and Porsche are less than 150 km away

- Optimum conditions for technological companies thanks to the excellent science and research structure

- Cluster management by MAHREG Automotive

Top Mobility Business Cluster

In Saxony-Anhalt, diversity in tradition and innovation is based around a whole range of renowned manufacturers.