Industrial Biotechnology

Saxony-Anhalt is a development centre for industrial biotechnology in the fields of:

Basic Chemicals

About seven billion euros in turnover are generated annually here at one of the world’s most attractive locations for the chemical industry. We are the East German federal state with the largest density of employees in the chemical industry, who in turn show a unique sales productivity. Research additionally accelerates the growth processes. For instance, scientists at the Fraunhofer centre in Leuna are working on replacing oil and natural gas with biomass as a raw material for the chemical industry.

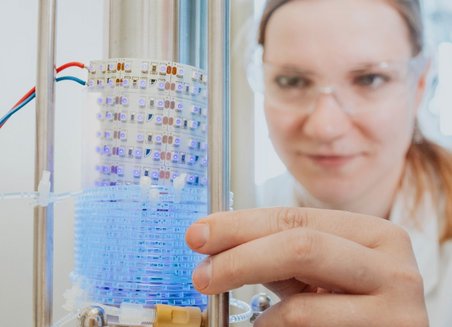

Scale-up and Contract Manufacturing

EW Biotech GmbH, a subsidiary of EW Nutrition GmbH, operates a multi-purpose biotech plant in Leuna, Germany. In addition to scale-up and contract manufacturing, the facility will enable expanded research and development activities in the field of bio-based chemicals, feed and food additives. EW Biotech and its experienced staff in the field of biotechnology and fermentation are thus creating the conditions to enable customers and partners to make the leap from the laboratory to industrial scale.

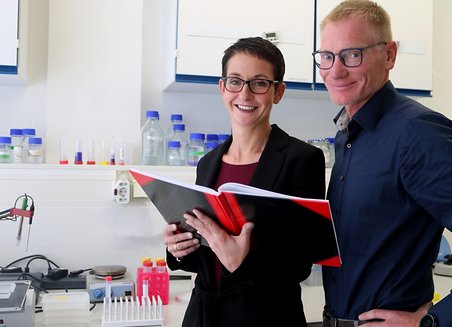

Isobutene

Global Bioenergies GmbH is a subsidiary company of the French start-up Global Bioenergies SA. The company has developed a process which enables the direct production of isobutene through the fermentative metabolisation of sugar-based raw materials.

“We may be a small company, but we want to be a catalyst between biotechnology and the chemical industry,” says Ales Bulc, Managing Director of Global Bioenergies. “We are breaking new ground with this innovative fermentation process and we want to further develop the process to market maturity.”

Gallery Global Bioenergies

Biopharmaceuticals

Specialists in red biotechnology, there are many in Saxony-Anhalt - as well as valuable active substances in biotechnology: Who would have thought that the tobacco plant could one day help to cure life-threatening illnesses? And that this discovery would come from Saxony-Anhalt? Just like other biotech innovations.

Raw Material Chitosan

The Hidden Champion Heppe Medical Chitosan on the weinberg campus in Halle (Saale) produces high-purity chitosan as a raw material for the pharmaceutical industry worldwide.

Biodegradable biopolymers as an alternative to oil-based materials are on everyone's lips and are already used in a wide variety of products such as packaging and films. Chitosan, a biopolymer that is still relatively unknown to the public, offers countless areas of application. In the medical field, for example, it improves wound healing as a component of wound dressings and dissolves naturally as suture material at the desired time.

Gallery Heppe Medical Chitosan

Bioplastics

In times of climate change and rising crude oil prices, bio-based plastics are becoming more and more significant. Furthermore, the demand for materials with new properties is high. Biotechnology has great and still untapped potential.