Sophisticated tubing for innovative medical technology

Novoplast in Halberstadt is one of the most innovative medium-sized companies in Germany

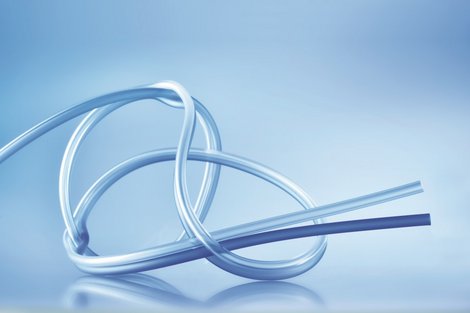

Plastic hoses are an indispensable part of medical technology. From injection tubes to intelligent catheters, the products are becoming increasingly sophisticated. Novoplast Schlauchtechnik GmbH in Halberstadt is a specialist in this field and a development partner for the manufacturers of medical devices.

“The tubes which pump an X-ray contrast medium into the blood vessels are under high pressure,” says Martin Oye, before telling us that the pressure can amount to 83 bars. After all, the medium has to be distributed to the finest capillaries. He compares this with the air pressure in a bicycle tyre, which averages just 25 to 30 bars. With hearing aids, on the other hand – he takes one, which is tiny, from the shelf – it is important that the plastic tubes are barely visible, but that they can transmit sounds exceptionally well.

The plastic tubes manufactured by Novoplast Schlauchtechnik GmbH in Halberstadt have a diameter of 0.1 to 50 millimetres and offer a wide range of applications. Martin Oye is responsible for the sales of the medical technology, 60 percent of which is sold in Germany. 40 percent are exported, mainly within Europe. “We work individually for our customers and develop products according to their requirements,” explains Martin Oye, telling us why Novoplast doesn’t have a product catalogue in the conventional sense. In addition to the aforementioned application in hearing aids and for injections of X-ray contrast media, the tubes are also used in infusion and endoscopic devices as well as for enteral nutrition. The company’s customers include well-known manufacturers of medical end-products. Oye discusses their long-standing business relationships and the high level of trust afforded in Novoplast as a development partner. “The customers appreciate our flexibility, our certified production processes and the technical expertise of our employees,” highlights the sales manager.

It is a region in which medical technology has a long tradition

As an example of the special developments, Martin Oye demonstrates the multi-chamber tube for a venous catheter. It transports three different substances which should not mix, but which should be administered to the patient at the same time. The double lumen tube, which finds use in ophthalmology, for example, has a similar design. It can be used to suck out and flush in liquid simultaneously.

These tubes are made in the clean rooms of the Halberstadt company on state-of-the-art extrusion lines or assembled with other components. “Precision and hygiene are the top priorities when it comes to the manufacturing of products that have medical approval,” says Oye, before offering an invitation to take a tour of the company. 120 employees work here: Process mechanics for plastics and rubber technology, business economists and the production team.

Novoplast Schlauchtechnik GmbH belongs to the Masterflex Group, a world market leader in the field of technical tubing and connections. The family business from Gelsenkirchen was still very young when the Berlin wall fell in 1989. It had been founded just two years earlier – and got into contact with “Polyplast Halberstadt” through the newly opened German border. The company first began to acquire expertise in the field of medical technology in the 1960s. With a wealth of technical experience and with a certain degree of start-up enthusiasm, the then “Polyplast” experts were convinced to co-found Novoplast Schlauchtechnik.

For Martin Oye, the first chapter of the company is local history, so to speak, although he was too young to be able to experience it first hand. After graduating from grammar school in 2002, the native of Halberstadt followed his parents. They were seeking work, and ended up in the Black Forest. After graduating in Business Administration, that was where Martin Oye stayed, working in the international sales department of a Tuttlingen-based medical technology company. When the much-travelled young man was on the look out for a new professional challenge in 2015, however, he found his way to Masterflex Group – and back to his roots in the Harz Mountains.

A fusion between diagnosis and therapy

As the website of Novoplast Schlauchtechnik says, “We bestow every tube with its own very special character”. So, manufacturing tubes is about more than just colour, diameter and shape. The focus is on modified material properties. Consistently interested in the transfer of knowledge, Novoplast maintains contacts with the Otto-von-Guericke-University OvGU in Magdeburg, the Fraunhofer Institute for Microstructure of Materials and Systems IMWS in Halle (Saale) as well as with innovative companies in the regions around Halle and Magdeburg. Some 75 companies from the medical technology sector are located in Saxony-Anhalt.

The testing of materials and material combinations is a future-oriented topic, says Martin Oye, referring to the bio-compatibility of plastic components. Above all else, artificial intelligence is also an innovation driver in the field of medical technology. The Chair for Intelligent Catheters (INKA) at OvGU is the perfect place for a lively exchange of knowledge.

The Novoplast sales manager keeps a close eye on the market developments. He can see the ever closer fusion between diagnosis and therapy. And he can also see the demand for absorbent materials and ever smaller instruments. ““It is frequently the case that tubing technology is also indirectly affected by these developments,” the expert knows and is already beginning to think about the possible paths to new “special markets”. He is happy to follow the futurologists and their visions on the ways in which medicine will develop over the next 10, 20 or 30 years. Martin Oye considers Novoplast Schlauchtechnik to be an active co-creator. “For the second time since 2016, we are one of the most innovative medium-sized companies in Germany,” he says, proudly announcing the result of this year’s TOP 100 innovation competition. The Masterflex Group convinced the jury in the category of “Innovative processes and organisation”.

Author: Kathrain Graubaum

HERE medicine has the right technology.

Innovative prostheses, surgical robots, telemedicine – the opportunities provided by medical technology are revolutionising diagnosis and treatment. Companies from Saxony-Anhalt are at the forefront of the development and manufacture of innovative products in medical technology.

> more information on the MedTech industry in Saxony-Anhalt