Advanced technology under the hood

Nemak Wernigerode focuses on light and environmentally-friendly cast parts

Cylinder heads have got what it takes to be a high-tech product. Integrated exhaust manifolds and intelligent thermal systems help to develop engines to be smaller and more compact. The car of the future is reliant on this, according to Dr. Dietrich Kahn. The managing director of Nemak Wernigerode GmbH declares that ultra-complex components are an international trend, helping to make vehicles lighter and more environmentally-friendly. Almost every second cylinder head from the aluminium foundry on the outskirts of the town in the Harz region combines the new properties within it. In two years, the proportion of the total production capacity should be increased to 70 percent.

Nemak is playing in the top division. Together with its customers, the largest independent aluminium foundry in Germany for cylinder heads is continuing to further develop products. An in-house research department ensures the technological progress, looking at how iron casting can be substituted for light metal in the best possible ways, among other things. “Our lead times are large. Our engineers today are already dealing with components which will be used in 2018,” reports Dr. Dietrich Kahn. In the meantime, processes can be simulated on the computer. This saves time. The company works particularly closely with the Volkswagen group. The components from Wernigerode are used in vehicles by Audi, Porsche and, of course, VW, among others.

Almost 90 percent of the 1.8 million cylinder heads produced each year and 600,000 chassis components go to this partner. VW awarded the Nemak Group, with its sites in Europe, the “Volkswagen Group Award” this year as one of its best suppliers. Chairman of VW, Martin Winterkorn said that the decisive criterion for the award was the company's pioneering technology and innovations with continuously high quality. One example of this is a particularly environmentally-friendly modern casting method. With the anorganic binding technology, which has been gradually implemented in Wernigerode since 2010, there is none of the usual smoke formation meaning harmful gases are no longer released into the environment.

“We consider ongoing innovations to be one of our most important competences,” explains managing director Frank Lehmann. This is why the Rotacast procedure was introduced about five years ago. The fundamental feature is the turbulence-free filling of moulds, in which the material cools in layers. This leads to a higher mechanical strength and a fine-grained structure. Cylinder heads cast in this way are used at Porsche and Mercedes among other companies.

The history of Nemak in Wernigerode dates back to 1935. An aluminium foundry began back then at the site, which supplied components for car engines and the aviation sector. Initially, the material for these uses was still new ground. Later in the GDR, every W 50 car and ZT 300 tractor had engine parts from Wernigerode. They came from the cast metal factory, the largest producer of cast aluminium in the country. In 1987, a production plant for cylinder heads for VW engines, which were also used in the Trabant car, started up. The cooperation that began then with the VW corporation helped the company to survive the reunification. At the turn of 1992/93, the Rautenbach Family took over the company as part of a reprivatisation and continued to develop it as Rautenbach-Guss Wernigerode GmbH. At the beginning of 2005, Rautenbach was integrated into the Nemak corporation. It is the world leading manufacturer of ultra-modern cylinder crankcases, cylinder heads and gearboxes made of aluminium. Nemak was founded in 1979 in Monterrey in Mexico and now has a network of 34 development and production sites around the world.

About 500 employees work at the site. Since 2005, the company has invested between five and six million Euro each year into modern production facilities. This includes testing equipment, which guarantees the high quality demanded by the automobile industry. Among other things, the company was the first foundry in Germany to use computer tomography.

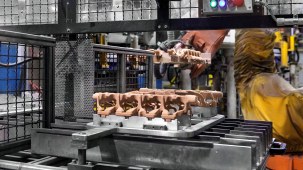

Caption: View of the production department at Nemak in Wernigerode.

Author: Klaus-Peter Voigt on behalf of IMG Investment and Marketing Corporation Saxony-Anhalt

Contact:

Nemak Wernigerode GmbH

Giesserweg 10

38855 Wernigerode

Telefon: 03943 6520

www.nemak.com