Grey was yesterday: APK AG presents fully decolourised plastic recyclates

Newcycling® of post-consumer waste proven successful on an industrial scale

The crowning achievement for any recycling company is obtaining pure plastic recyclates from mixed consumer waste. “2021 was a milestone year for APK AG. We were able to prove that our Newcycling®-technology can successfully recycle household plastic waste, and do so on an industrial scale. We were able to fully achieve the ambitious goals we had set for scaling and decolourisation”, declares Klaus Wohnig, CEO of APK AG.

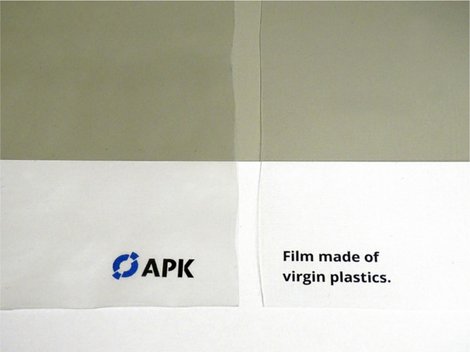

Over the course of 2021, APK implemented an industrial-scale production campaign in several phases at its Merseburg recycling plant. The input material used for the ‘post-consumer Newcycling® campaign’ was film waste from household collections. The first phase generated excellent results with regard to problem-free processing, yield and mechanical values of the recyclate. With a view to decolourisation, the process parameters were refined in an intermediate laboratory phase. The modified parameters were successfully implemented in November 2021 in the second phase of the campaign by the development team led by Hagen Hanel, head of APK’s Plastics Recycling Innovation Centre. “Our hard work has paid off in full”, states Dr Jürgen Flesch, APK board member who oversees production and technology. “We were able to obtain a light-coloured LDPE-recyclate from mixed, flexible household waste, which was then processed into a film”. The analysis of the material obtained revealed excellent colour and transparency values. “The L value of our ‘campaign film’ is close to that of films produced from virgin plastics”.

Transparent – LDPE-film made of recyclates from APK’s post-consumer Newcycling®-campaign (left) and film made of virgin plastics (right). Copyright APK AG.

Recycled plastics are in greater demand than ever – especially in the packaging segment – and the quality requirements for them are markedly increasing. “Proof of concept is an important step on our pathway to building new Newcycling® plants”, explains Maik Pusch, Director of Corporate Development at APK AG. APK is ambitiously moving forward with its expansion and, together with initial partners in the plastics value chain, is planning to set up several new plants over the coming years.

About APK AG

APK was founded in 2008, with the vision of producing the purest possible plastic recyclates from plastic waste, with characteristics comparable to those of virgin plastics. With their Newcycling® process, APK’s research team and engineers have developed an efficient recycling technology that combines mechanical and solvent-based processes. At present, APK employs a staff of around 150 employees at its Merseburg (Germany) location. The production plant features a recycling capability of up to 20,000 tonnes per year. APK’s recyclates are marketed under the names Mersalen® and Mersamid®.

Source: www.apk-ag.de