Electric and Hybrid Vehicles

Saxony-Anhalt is taking on the pioneering role in the field of new mobility in numerous niches related to production processes. The companies and research institutions in the state provide the ideas and conditions, in various areas, to enable the OEMs to build the cars of the future:

Lightweight Design - HERE, experts make light work of innovations.

The car of the future is above all else a resource-saving vehicle. Modern lightweight construction faces new requirements: due to the objective of reducing energy consumption, and due to the challenges that new types of drive pose for the mobility of the future. The industry sectors of aluminium and composites play an essential role in this. But it has long since been the case that the questions of the lightweight construction of the future can no longer be answered with a single material. Saxony-Anhalt is working on new solutions in the areas of metal working and processing and in the field of plastic and new materials.

You will find more lightweight Design innovations from Saxony-Anhalt HERE.

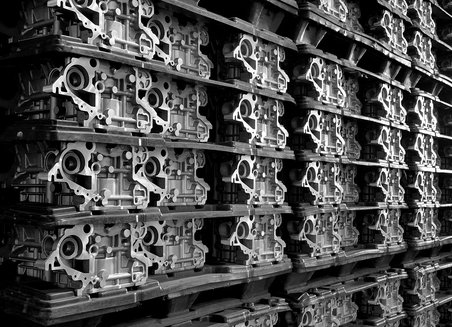

Fixture construction and process and production technologies

With the construction and design of prototypes, assemblies and complex assembly jigs, fixture construction provides the ideas and conditions for innovations in automobile construction. Fixture construction here accompanies new models and designs from the idea to the first prototypes to the small series. New process and production technologies are developed and implemented in close cooperation between universities, research institutes, tool and machine manufacturers, and automotive suppliers. Materials are being optimised, manufacturing processes made more efficient, and production flows improved. The new technologies are applied in enterprises in Saxony-Anhalt or established in companies around the world via technology transfer.

Prototypes and micro-series products - Vorrichtungsbau Giggel GmbH in video

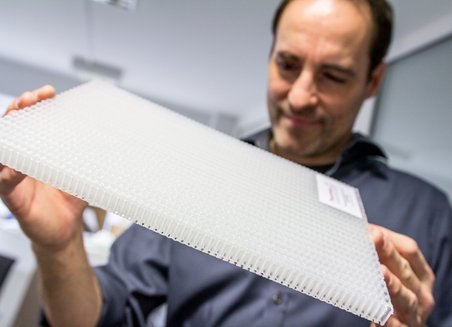

In the north of Saxony-Anhalt, the company Vorrichtungsbau Giggel GmbH develops prototypes and micro-series products for the automotive industry. The company supports all of the major OEMs and vehicle manufacturers with the development of pioneering components for the next generation of vehicles. Above all, the use of new materials is especially important in this field of New Mobility.

Autobody structures, battery holders, and cooling systems for fuel cells are increasingly being manufactured from malleable sheet metal or grades of aluminium whose strength nears that of steel. Vorrichtungsbau Giggel GmbH develops new products all the way from the test bench to market maturity for its customers. The latest highlight: in cooperation with MIFA, the industrial designer Martin Wiesner, the Harz University of Applied Sciences and the IKAM Institute, the company has developed the prototype of a chainless e-bike.

New Drive Technologies

Drive and traffic systems are being re-thought in Saxony-Anhalt. Thanks to technical innovations in this area, the state is in the process of establishing itself as a research and production site for drive technologies. With its expertise in the area of electric drive systems, Saxony-Anhalt is making a successfully entry into the end customer market for automobility and special vehicles.

First ambulance with a hybrid engine - Ambulanz Mobile GmbH

Saving lives with design: a task which is fulfilled by the ambulance of the future. And this is a project to which the company Ambulanz Mobile from Schönebeck has made a major contribution. The company develops unique concepts for ambulance vehicles. An aerodynamic roof structure with an integrated blue light not only provides for a modern and elegant look, but also results in fuel savings of at least two litres per 100 kilometres.

But such factors only indirectly result in the saving of lives. The interior of the ambulance is the actual safety factor. The auxiliary equipment for the emergency team is stowed away securely and is easily accessible, making the TIGIS rescue vehicle, which was developed in Schönebeck, one of the safest in Europe. And the design of the vehicles isn’t the only pioneering factor. In collaboration with Otto-von-Guericke University Magdeburg, Ambulanz Mobile is developing the first ambulance with a hybrid engine for the rescue operations of tomorrow.

Battery and Fuel Cell

In addition to battery-based electromobility, hydrogen technology is also gaining considerable influence on mobility. Saxony-Anhalt is here excellently positioned in the field of storage solutions and with its long-time testing centre for fuel cells and batteries. The project HYPOS (Hydrogen Power Storage & Solutions East Germany) is devoted to regenerative hydrogen production, storage and distribution, and operates a demonstration plant for hydrogen electrolysis. In 2018 the “Centre for Method Development” (CMD) was brought into being. The development centre, which will be settled at the Otto von Guericke University Magdeburg, will carry out research into innovations in the area of electromobility, and on the reduction of emissions and fuel consumption. Furthermore, locally based companies are given the possibility of testing newly developed products on test benches.

Test benches for fuel cells and batteries - HORIBA FuelCon GmbH in Video

The latest batteries and energy management systems are key requirements for the mobility of the future. Analyses of their service life, performance, degradation and cycle stability form part of the tests completed by HORIBA FuelCon GmbH.

With test benches for AIRBUS, Audi, BMW, BOEING and other OEMs, the company is a leading manufacturer. Its products range from small cell test benches, large fuel cell systems, to large battery packs that are used as a traction battery for motor vehicles. HORIBA FuelCon GmbH has been an expert in the area of high-performance solutions for several years. On the basis of test parameters of -40 °C to 120 °C on battery test benches and the TrueData impedance analysis unit, the determination of precision measurement data is possible.