Small But Effective

Intensive research is being carried out in Saxony-Anhalt into biorefinery concepts for microalgae

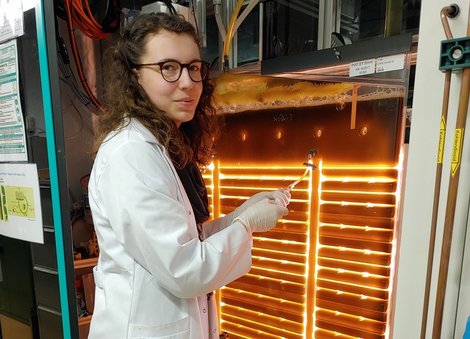

Scientist Laura König-Mattern from the Max Planck Institute for Dynamics of Complex Technical Systems in Magdeburg may soon be playing a prominent role in the chemical and bioeconomy sector, one of Saxony-Anhalt’s five designated leading markets. She is working on a biorefinery concept for breaking down microalgae into its basic building blocks, which can then be used to make a wide range of active biomaterials with huge potential.

According to König-Mattern, the term macroalgae refers to the seaweed that you find in the sea, which has proper leaves. “Microalgae, on the other hand, are monocellular and only a few micrometers in size.” At the Max Planck Institute, the microalgae are cultivated and reared in small flasks. They are also grown in a 28-liter large reactor when König-Mattern needs larger quantities of biomass for her experiments.

Making the most of biomass

During cultivation, the cell density of the microalgae in the culture medium constantly increases. They are initially light-colored, but turn dark brown by the end of the process. When they have reached this point, the cells are stationary, meaning they have stopped reproducing and can be harvested. Over several stages, the cell paste and its valuable contents are separated from the culture medium. Methods used thus far involve drying the algae, but this requires a lot of energy. König-Mattern has a different approach: she is researching suitable solvents for extracting the target molecules from the wet biomass. “My biorefinery processes really makes the most of the biomass, rather than using just a few parts of it,” she explains. König-Mattern uses computer-based quantum mechanical calculations to screen a large data set of solvents in order to find the right solvent for each molecule. This makes the experiments quicker and simpler. “A lot depends on the separation stages,” she says. “That’s why research in this area is so important. Green solvents are cost-effective and have a low environmental impact.”

Separating the biomass into its basic building blocks of protein, carbohydrates, fats and pigments enables König-Mattern to obtain an entire range of active biomaterials from the algae. “We want to make optimum use of the biomass, rather than extracting only one target product from the cells,” she says. These substances are still fairly niche, but their potential is huge. The deep-red pigment fucoxanthin, for example, is used as a natural colorant. Lipids can be converted into biodiesel. Polyunsaturated fatty acids from microalgae are a sustainable alternative to fish oil capsules.

Laminarin, which is found in the carbohydrate fraction, can be used as a natural pesticide. Lots of microalgae also produce essential amino acids in quantities that can otherwise generally only be found in meat.

Support from the state for leading clusters

“The market-ready stage is still a long way off,” says König-Mattern. She studied biosystems engineering, systems engineering and cybernetic engineering at the Otto von Guericke University in Magdeburg and has been researching suitable solvents for biorefineries at the Max Planck Institute in Magdeburg for her PhD since September 2019. She has been awarded a grant to help fund her research from the Christiane Nüsslein Volhard Foundation, which promotes science and research. This funding, together with the excellent research environment in Saxony-Anhalt with its many universities and institutes, have supported her work. “Saxony-Anhalt is home to first-class researchers and a fantastic research infrastructure with an international focus,” she says. The department at the Max Planck Institute in Magdeburg where König-Mattern researches collaborates with other research institutes such as the Fraunhofer Center for Chemical-Biotechnological Processes in Leuna, but also works with industry partners such as Roquette in Klötze. The department also has strong international ties and is working with Swiss scientists on research into how lignin, which is found in wood, can be converted into chemical substances.

Saxony-Anhalt boasts a large network of institutions, companies and research institutes that specialize in the bioeconomy; the leading BioEconomy cluster alone has 75 partners. In addition to funding from the German government, BioEconomy has been receiving financial support from the state of Saxony-Anhalt since 2013. In mid-2017, this support was extended to 2026.

Author: Anja Falgowski/IMG Saxony-Anhalt

As a long standing location for the nutrition, chemicals, wood/cellulose and agricultural economy,

we have excellent knowledge of renewable resources and biotechnology processes as the basis for industry, energy and nutrition.