A hydrogen village in trial operation

In the era of the energy transition, Saxony-Anhalt is demonstrating how buildings can be supplied with heat and power intelligently and efficiently by a green hydrogen network

At the Bitterfeld-Wolfen Chemical Park Center of Excellence, a new chapter in the story of green hydrogen is beginning. In the H2 test village, the supply infrastructure and the end uses are being tested under real-life conditions. The materials and technologies that enable the fuel to be used to supply energy to buildings also play an important role.

The chemical parks in Leuna, Merseburg and Bitterfeld-Wolfen in central Germany were once synonymous with unpleasant smells and contaminated ground. Now they form part of a model region for hydrogen. Here, the HYPOS consortium (Hydrogen Power Storage & Solutions East Germany) is developing a complete value chain for green hydrogen produced from renewable electricity and is being funded by the German Federal Ministry of Education and Research as part of the Twenty20 – Partnership for Innovation program.

Ideal conditions for the hydrogen revolution

There are good reasons why the model region of the HYPOS network is located in central Germany. The second-longest hydrogen pipeline in Germany runs through Saxony-Anhalt and guarantees the efficient transport of green hydrogen. Other features of the location include the presence of several chemical and fuel companies and huge underground salt caverns that can store enormous quantities of hydrogen. Renewable energy makes up 60 percent of the power consumption in Saxony-Anhalt, which is another reason why the hydrogen village has been located here. Other measures have also been taken, for example, 675 meters of plastic piping has been laid to replace the standard metal pipes.

Natural gas infrastructure is repurposed

In order to demonstrate that the existing natural gas infrastructure can also be used with pure hydrogen, a hydrogen test infrastructure was set up in 2019 on a 12,000 square meter site in the middle of the chemical park.

The end applications for hydrogen are also being investigated here and a range of different consumers are being connected to the H2 network. This includes providing a hydrogen supply to buildings. Anyone who takes one of the guided tours through the hydrogen village during the open day (event.enviam-gruppe.de/hypos-h2-netz) will get an idea of how a residential area could be supplied via an H2 network in the future. To ensure that this does not remain merely a vision, the infrastructure and the use of hydrogen are being evaluated from a technical, financial and environmental perspective on the test site.

H2-Home – Hydrogen-powered combined heat and power plant provides heating and cooling

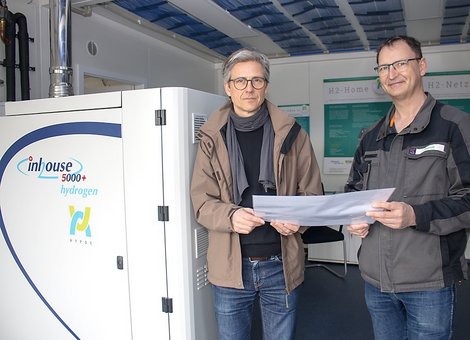

H2-Home is a HYPOS project that involves, among other things, the development and implementation of a hydrogen fuel cell combined heat and power (CHP) plant for new homes and residential areas. Fuel cell CHP plants can be used not only to heat buildings but also to supply them with electricity, as H2-Home project leader Steffen Theuring from inhouse engineering GmbH explains. The Berlin-based company develops and constructs H2 CHP plants of this kind. “At the moment hydrogen is more expensive to produce than natural gas,” says Theuring, “but the cogeneration of heat and power is highly efficient.” The breakthrough for the company’s research and development department came when it made contact with the HYPOS network. The H2 fuel cell CHP plant known as inhouse5000+ Hydrogen, which was developed as part of a HYPOS project, allows hydrogen to be used to produce electricity and heat for the winter and has an additional heat pump for cooling buildings in the summer. The partners in this HYPOS project are DBI-Gas- und Umwelttechnik GmbH Freiberg, the Freiberg University of Mining and Technology, the Fraunhofer IMWS Halle (Saale) and the Berlin-based electronics service provider ENASYS.

Anyone who visits the glowing “green” innovation pavilion in the hydrogen village on either a cold or a hot day will immediately notice that the cogeneration of heating or cooling and power really works.

Smell of sulfur gives a warning

A lot of development work is needed to integrate the hydrogen CHP plant into a building as effectively as possible, according to Steffen Theuring, the project leader. He mentions bringing the connection pressure of the hydrogen close to the pressure of the existing building connection system for natural gas. The hydrogen has to be transported at high pressure in the transmission pipeline and at low pressure in the distribution networks for end users. Enough progress has been made with the development of the H2 CHP plant that it can now provide an emergency electricity supply and function as an independent supply unit.

Steffen Theuring raises the issue of increasing the safety levels in an H2 network, which is the only way of ensuring that hydrogen is accepted by end users. Research is also underway into enabling end users to smell hydrogen, which is actually an odorless gas. An odor is added to the hydrogen that signals danger to almost anyone who smells it. In the H2 village, the fuel cell has been tested with sulfurous smells. “However, the odor must be removed from the hydrogen before it enters the H2 CHP plant,” explains Theuring and adds that this costly process of preparing the gas reduces efficiency and therefore needs to be improved.

Energy on the road in a car trailer

“Until now we have not had an intelligent, decentralized supply infrastructure for industrial and commercial sites with small hydrogen applications,” says Torsten Birth, head of the Energy and Resource-Efficient Systems group at the Fraunhofer Institute for Factory Operation and Automation IFF in Magdeburg. The group is running a research project called MMH2P. The acronym includes the terms “mobile,” “modular,” “hydrogen” and “portable.” The prototype of this service storage system is on four wheels and weighs less than a car trailer. It is intended to fill a gap left by the conventional stationary and mobile storage systems in the hydrogen infrastructure and can be used anywhere where H2 producers and consumers are not connected by pipelines and where stationary and transportable liquid and gas storage facilities are not a suitable solution.

The small-scale distribution system will undergo pilot testing in the hydrogen village where it will tap into the H2 network and supply the fuel to H2-Home applications.

Alongside industrial and commercial parks, Torsten Birth believes that other potential customers for the mobile hydrogen storage system include public utility companies and municipalities that need their own supply and police and fire service vehicle fleets.

Author: Kathrain Graubaum/IMG Saxony-Anhalt

Saxony-Anhalt offers good starting conditions for the development of a forward-looking hydrogen economy.

As a traditional chemical site, the state has many years of experience with hydrogen utilization in the Central German Chemical Triangle.