Technologies of Digitalisation – Made in Saxony-Anhalt

In Saxony-Anhalt, diversity and dynamism inspire developments - some IT companies are now among the world's best with their solutions and products. Key technologies are important drivers of innovation and secure Saxony-Anhalt's strong and competitive economy.

Big Data

Big Data – the pile of data available in the company – or – how analysis programs derive customer-relevant information from large amounts of data.

The efficient use of Big Data means a decisive competitive advantage for companies. It requires intelligent algorithms, a strategy and core issues to draw „digital“ added value through the Big Data project.

Datameer is a global IT company that was founded by a former student of the Martin Luther University Halle and successfully expanded to California, the famous Silicon Valley. The core business is analysis programs that derive customer-relevant information from large amounts of data. Despite its worldwide success, Datameer continues to invest in the expansion of its location in Halle (Saale), because it wants to take advantage of the excellently trained, committed and team-oriented IT students from Halle (Saale) and the surrounding area.

The Otto-von-Guericke University Magdeburg is home to the world's largest SAP University Competence Center (SAP UCC). It operates and supports SAP solutions for more than 500 institutions in Europe, the Middle East and Africa - from vocational schools to elite universities, research institutes and industry partners. Here, science and industry benefit from the latest technology in teaching, research and co-innovation.

IT Safety

There is no such thing as “one hundred percent security” and there probably never will be.

According to the definition of the German Federal Office for Information Technology Security, IT security is “a state in which the risks that arise during the use of information technology due to threats and weaknesses are reduced to an acceptable level with the use of the appropriate measures." For digitalisation to be able to succeed, cyber security is an essential prerequisite, and the number of companies operating in this area in Saxony-Anhalt is growing accordingly.

For example, the company AV-Test GmbH has become a world-leading provider of IT security and anti-virus research services; the company DIGITTRADE GmbH is developing and producing external hard disks and USB sticks with hardware encryption, as well as certified solutions for the storage of sensitive data on mobile storage media. It therefore comes as no surprise that IT security and data protection are key focal points of the "Digital Agenda" which is currently being developed in Saxony-Anhalt under the aegis of the Ministry of Economics, Science and Digitisation.

Cloud Computing

European Data Hub in Biere

Digital business processes generate masses of data, the new currency of the economy. In order to turn the „rough diamants“ into truly „high-calibre diamonds“, you need a place to store and evaluate them, a data control centre. Deutsche Telekom has developed Biere near Magdeburg into a European Data Hub with a consistent cloud partner strategy. Nowhere else in the world are leading providers of cloud technology side by side in a data center. This makes beers unique and attractive for customers and partners.

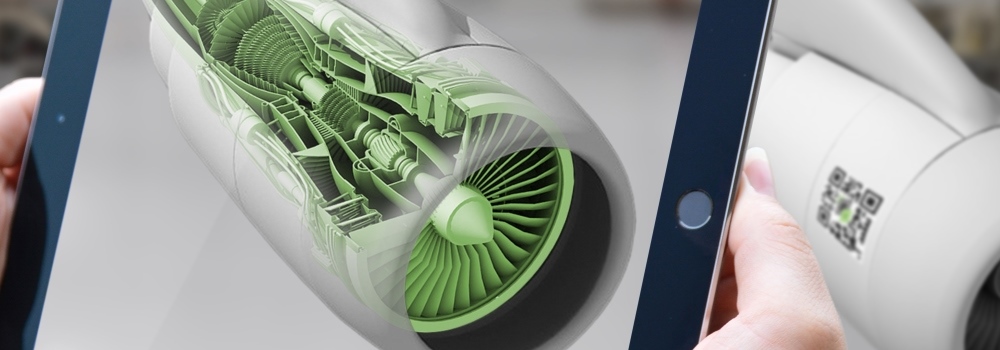

Virtual and Augmented Reality

Concepts from Saxony-Anhalt are helping the technology to achieve its breakthrough. These days, augmented reality (AR) is an indispensable part of the process of digitalisation for companies and researchers alike. Visualising objects in virtual form saves costs, time and effort. This is because AR enables the precise visual and spatial visualisation of invisible characteristics and projects directly in their actual environment. Companies and research facilities in Saxony-Anhalt are working both on and with AR solutions.

3D- Printing

How 3D printing changes our economy

Shoes, T-shirts and mobile phones from the 3D printer: In the future, consumers will simply produce their desired products themselves on site. This challenges economic processes. But professional 3-D printing brings opportunities: prototypes and small series can be produced in a high quality, cost effective and fast. Rapid prototyping also creates high-quality end products, trade fair models and spare parts at various stages of development. 3D printing solves what is not possible in classic manufacturing in terms of filigree.

Artificial Intelligence

Artificial intelligence in industrial maintenance

The digitisation of the economy is continuing to progress. Multifunctional and high-precision sensor systems, modern network technologies and novel algorithms create the basis for the use of forward-looking, software-based maintenance strategies for modern machinery and production plants. The mapping of the high complexity of such production systems into meaningful and fast control and analysis algorithms can only be achieved on the human-cognitive level with a very high economic effort. Intelligent algorithms offer a cost-effective and quickly realizable alternative.

Indalyz Monitoring & Prognostics (IM&P) GmbH is a software company focused on the implementation of predictive maintenance software solutions for machines, plants and vehicles. The software product developed especially for this purpose is based on Prof. Dr. Michael Schulz's many years of research work on artificial intelligence, complex systems and dynamic structures.